Automatic tray

feeding system

What’s an automatic tray feeding system?

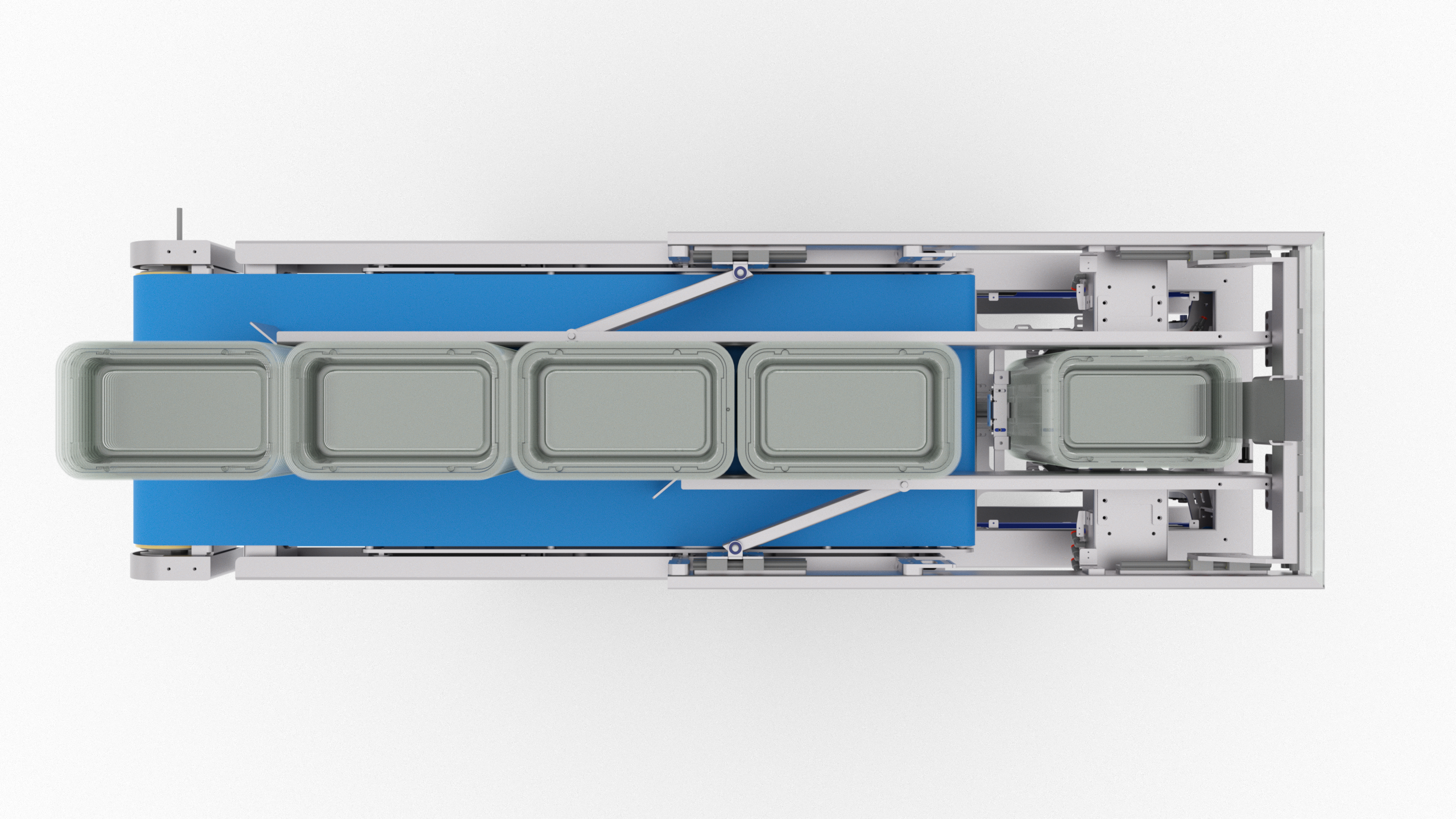

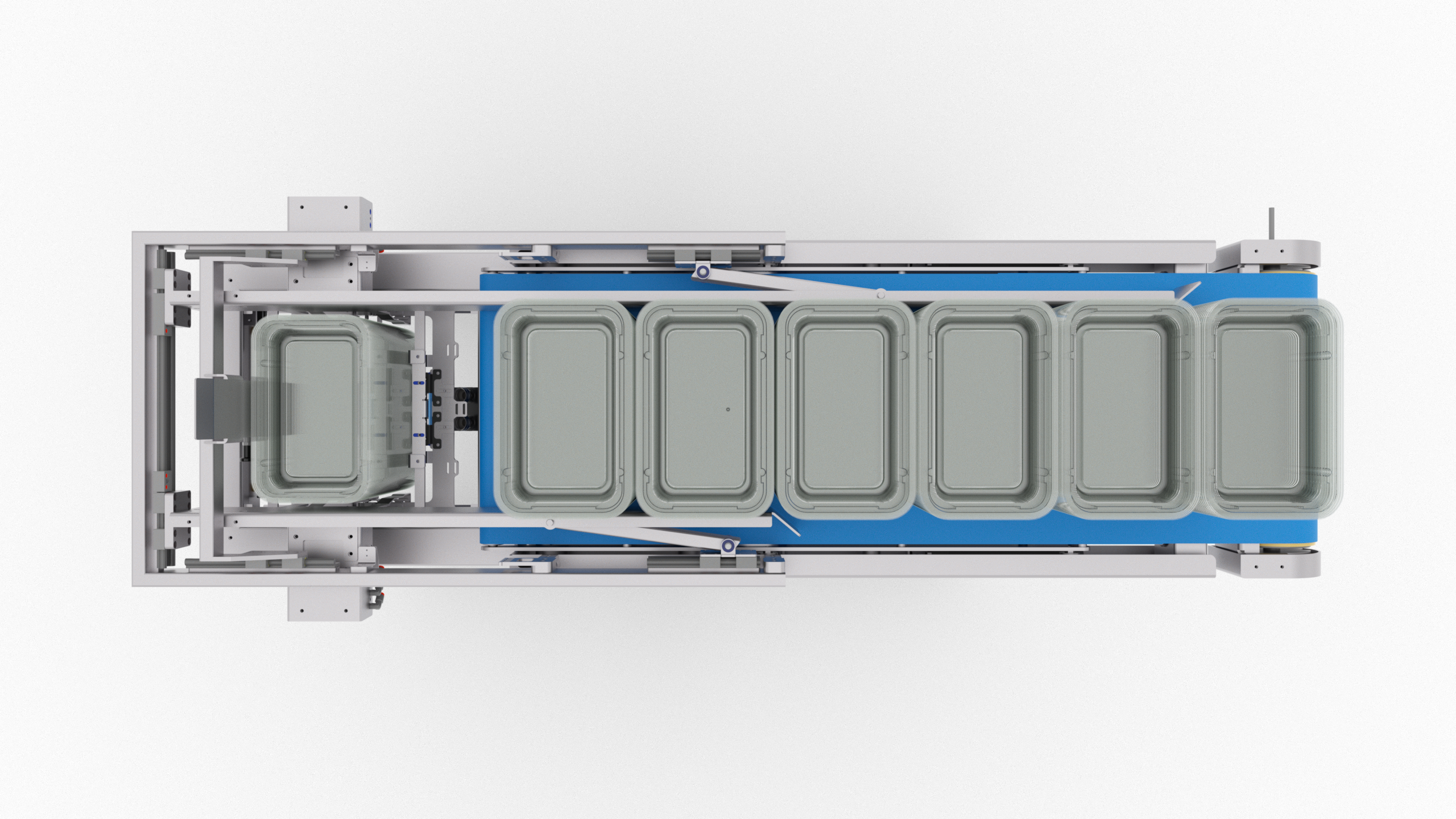

The denesting machine is composed by two main essential elements. The first is the most obious one, is the tray nesting system, but this system needs to be fed with stacks of trays. If the denester runs at a fast speed of trays, the user will have to attend to the machine a bunch of times. That’s when the automatic feeding system makes sense.

The automatic trays feeding system is a buffer full of stacks of trays. The stacks of trays are stored there, and feeds the tray denester system charging them one by one.

Be less pending

The tray denster allows to the producers to consistenly feed a production line of plastic trays, cardboards or other kind of ecologic trays. But when looking for the automation level that a tray denester gives, we don’t want to have a worker feeding the denester with stacks of trays. It just doesn’t makes sense… right?

The automatic tray feeding system it’s not only a buffer of trays, it controls when is the optimal moment to do the process of charging the stack to the denester allowing to denest trays in a regular way.

The key benefit of an

automatic tray feeding system

The key benefit is simple: gives time to the user to be able to attend other parts of the line while no action is needed in the denester.

The capacity of the automatic feeding system will depen of the dimensions of the trays and the orentation of them. But at least, the machine will allow to have 4 times more trays in the global of the denester than without the denester. It means 4 times more autonomy of the machine without any interaction of the user. Allowing the operators do other tasks on the production line.